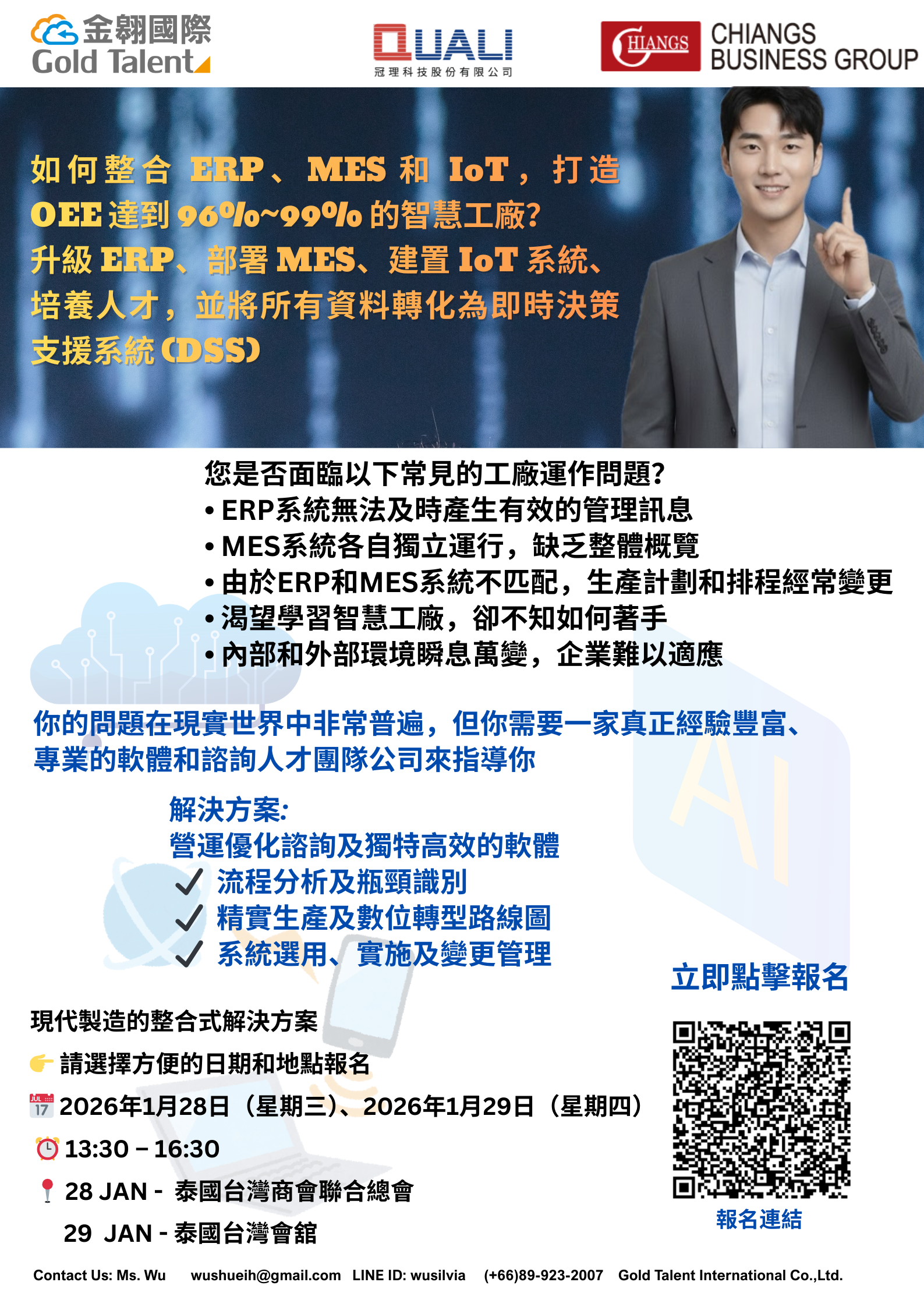

【台泰時報曼谷電】隨著製造業加速導入數位化管理,如何讓企業資源規劃系統、製造執行系統、IoT,與生產現場真正接軌,成為旅泰台商與在泰製造業普遍關注的課題。為回應此一趨勢,金翱國際(Gold Talent International)攜手冠理科技股份有限公司(QUALI of Chiangs Group),將於 1 月底在曼谷舉辦「ERP、MES 與 IoT 整合智慧工廠」主題專題說明會,聚焦製造業在系統整合與數據即時化過程中的實務挑戰。

主辦單位指出,許多工廠在導入企業資源規劃系統(ERP)與製造執行系統(MES)後,仍面臨管理資訊無法即時反映現場狀況、系統各自獨立運行、資料不相容影響生產排程等問題,導致智慧工廠推動進度受限。如何整合分散的系統與數據,並轉化為可支援現場決策的資訊架構,已成為企業提升營運效率的重要關鍵。

本次專題說明會將從實務應用角度出發,說明 ERP 升級、MES 部署、與物聯網(IoT)系統建置之間的整合邏輯,並分享製造業在流程優化、關鍵瓶頸辨識、與系統選型上的實際經驗。透過案例解析,協助企業更清楚理解不同導入階段的重點與可能面臨的挑戰,建立可循序推進的智慧製造思維與階段性行動方案。

活動內容涵蓋生產流程分析、智慧工廠導入策略、系統實施與變革管理等主題,邀請參與對象,包括製造業經營者、廠長、資訊主管,以及負責數位轉型規劃的決策人員。主辦單位強調,說明會除探討系統與技術面向,也將觸及組織運作與人員培訓等實務議題,協助企業在轉型過程中降低摸索成本,提高數位轉型投資報酬率。

為方便企業依行程報名參加,本次說明會,將分兩場辦理:

一、2026 年 1 月 28 日(三)下午 13:30 至 16:30 於「泰國台灣商會聯合總會」舉行

二、2026 年 1 月 29 日(四)下午 13:30 至 16:30 於「泰國台灣會館」接續辦理

主辦單位表示,期盼透過此次交流,協助旅泰台商,與在地製造企業,更清楚掌握智慧工廠導入的整體脈絡,讓系統整合與數據應用成為提升營運效能的實際工具。

As manufacturing industries accelerate the adoption of digital management, how to effectively connect enterprise resource planning (ERP) systems, manufacturing execution systems (MES), IoT technologies, and the shop floor has become a widely shared concern among Taiwanese businesses in Thailand and local manufacturers. In response to this trend, Gold Talent International, in collaboration with QUALI of Chiangs Group, will host a thematic seminar titled “ERP, MES, and IoT Integration for Smart Manufacturing” in Bangkok at the end of January, focusing on the practical challenges manufacturers face in system integration and real-time data utilization.

According to the organizers, many factories that have implemented ERP and MES systems continue to face issues such as management information failing to reflect real-time shop-floor conditions, systems operating in silos, and data incompatibility disrupting production scheduling. These challenges have constrained the progress of smart factory initiatives. Effectively integrating fragmented systems and data, and transforming them into information architectures that support on-site decision-making, has become a critical factor in improving operational efficiency.

The seminar will take a practice-oriented approach, explaining the integration logic among ERP upgrades, MES deployment, and IoT system implementation. It will also share real-world manufacturing experiences in process optimization, bottleneck identification, and system selection. Through case analyses, the event aims to help enterprises gain a clearer understanding of key focus areas and potential challenges at different implementation stages, thereby fostering a structured smart manufacturing mindset and phased action plans.

The program will cover topics including production process analysis, smart factory implementation strategies, system deployment, and change management. The event is designed for manufacturing business owners, plant managers, IT managers, and decision-makers responsible for digital transformation planning. The organizers emphasize that, in addition to systems and technologies, the seminar will also address organizational operations and workforce training, helping companies reduce trial-and-error costs and improve the return on investment of digital transformation initiatives.

To accommodate participants’ schedules, the seminar will be held in two sessions:

1. Wednesday, January 28, 2026, from 1:30 PM to 4:30 PM, at the Thai-Taiwan Business Association (TTBA)

2. Thursday, January 29, 2026, from 1:30 PM to 4:30 PM, at the Taiwan Association of Thailand

For registration details, please refer to the event announcement: Click here to see more content

The organizers expressed their hope that this exchange will help Taiwanese businesses in Thailand and local manufacturing enterprises gain a clearer understanding of the overall framework for smart factory implementation, turning system integration and data utilization into practical tools for enhancing operational performance.